CLT is hastening the adoption of engineered wood in the construction industry.

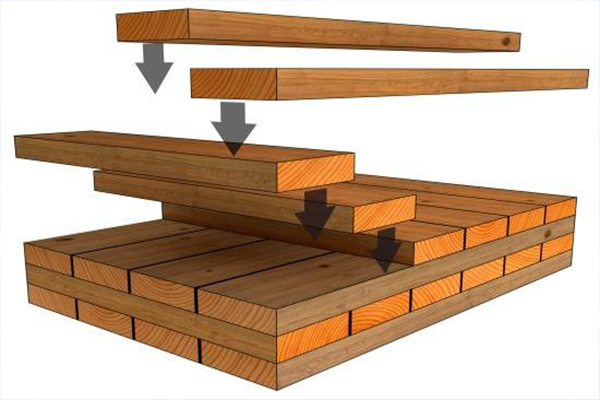

The construction sector is beginning to use mass timber items, which are engineered wood composites with a large scope. CLT is a relatively new wood product with enormous potential for greatly increasing the use of wood materials in construction. CLT is made up of massive boards made up of many layers of structural grade softwood boards. Each layer of boards is normally glued on the wide faces of each board, positioned perpendicular to adjacent layers and symmetrically so that the outer layers have the same orientation. Cross-laminated timber (CLT) is a type of mass timber building that differs from today's steel and concrete construction. When compared to carbon or steel, it is a renewable resource with a low carbon footprint since carbon is sequestered within the wood it is made from.

Technology Trends in the Cross Laminated Timber Market

Today's manufacturers use a subtractive process, first constructing the panels and then cutting out windows and doors—a wasteful process—whereas an advanced manufacturing plant would use an additive process, such as a 3-D printer. This places wood only where it is required, leaving space for doors, windows, plumbing, mechanical, and electrical lines. The machines could install various materials between the sheets in a LEGO-like fashion to add soundproofing, fire resistance, and other capabilities. Architects would be able to use all of the technology available to them to tailor materials to their specific requirements. It's about requiring the wood [panel] to perform a variety of functions through engineering and technology. The assumption is that architects already think in this manner.

Another strongly held belief is that the key to success for timber construction lies in cross-laminate timber technology. Cross-laminated timber has many unbeatable advantages over steel and mineral-based building materials. Nevertheless, the future may well lie in the development of hybrid technology, where various building materials with different strong points are combined into a single building system, thereby opening up new architectural possibilities.

Cross-laminated timber market technology trends are improving, which means that demand for these materials is rising. This new factor has resulted in the increased use of cross-laminated timber in many industries, including construction, interior design, and furniture. The industry is expected to maintain its current growth rate.

Industry Growth

Industry Growth

The growing demand for cross-laminated timber, an environmentally sustainable construction material, is due to increased consumer awareness of the environmental damage caused by the cement and brick manufacturing processes. As a result, consumers and technicians are shifting their focus to the use of sustainable materials in the construction of buildings and other infrastructure, such as wood. Because CLT is made of wood, many governments support its use in construction and offer monetary and space-liberty benefits to users.

Furthermore, when compared to traditional construction materials, lumber provides better thermal and acoustic insulation, reducing the use of harmful products like glass wool and foamed plastics for building insulation. As a result, the material's environmental benefits have been a major factor in its popularity in the construction sector. Due to technological developments, cross-laminated lumber is expected to become more popular in building. Technological developments have made buildings up to ten stories tall possible.

Asia-Pacific will be the largest region in the modular and prefabricated non-residential building construction market in 2021. Africa is expected to be the fastest-growing region in the forecast period. The regions covered in the modular and prefabricated non-residential building construction market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa.

Global Market for CLT

The increased construction of buildings and infrastructure in developing countries, where many projects are planned in remote locations without the use of concrete or steel, is driving up demand for CLT. The most powerful players in the global cross�laminated timber market are major companies. These companies have played a critical role in changing the rules of competition in this industry and guiding the market toward long-term growth. Many companies are increasing their investments and seeking new partners in order to increase their market share.

Construction is expected to grow rapidly in the coming years, particularly in Asia-Pacific and Latin America. Despite being numbed by the occurrence of the COVID-19 pandemic, large-scale investments planned by the governments of India, China, Brazil, and other Pacific countries are expected to result in construction sector growth. This expansion is expected to translate into market growth as both governments and construction companies seek sustainable building materials to develop infrastructure while meeting WHO CO2 emission standards. Because wood is a known carbon sequester, its use in construction is expected to increase, propelling the growth of wood products such as XLam. These factors are likely to fuel market expansion.

Segments and Expansion

As a result of increased worldwide business development operations backed by private and public investment, the business application sector will have a considerable market share. The industrial application category will have a high market growth rate due to increasing industrial expansion and the need for infrastructural growth in developing countries such as China, India, and Brazil.

The consumer-driven cross-laminated timber sector is led by Europe. North America and Europe will have a substantial proportion of the cross-laminated timber market due to their established construction industries and expanding green building practises for residential and commercial projects. The Middle East and Africa will have a substantial market growth rate due to the rapid expansion of economic and institutional infrastructure in the region.

Depending on the component, cross-laminated timber is classified as either adhesive�bonded or mechanically fastened CLT. Adhesively bonded CLT will have a significant market share. It could be due to the product's numerous advantages, such as excellent insulation and fire-safety qualities.

Sustainability

Cross-laminated timber is a material that is used to make the core of all non-concrete building materials. It can be likened to a timber frame, with the benefit of being stronger and more stable. The wood fibres are layered in a way that structurally reinforces them, which allows the material to have high loads and long-term efficiency. The industry has been growing rapidly because it provides environmental benefits such as fewer CO2 emissions and lower costs.

CLT panels offer positive environmental benefits, including carbon storage and low greenhouse emissions during manufacturing, and they are recyclable. The panels reduce construction time compared to some other building methods, require a shorter learning curve for installers, and create a healthier environment. It is a renewable material that can be made from relatively small-diameter trees and those affected by insects and diseases, which would not be used otherwise.

CLT is a suitable choice for heavy framework manufacturers, expanding interest in CLT and giving a green choice to steel and cement. CLT offers high strength and the structural simplicity needed for cost-effective buildings, as well as a lighter environmental footprint than concrete or steel. CLT board manufacture considers a wide scope of board sizes and thicknesses. Architects use CLT boards as load-bearing plate components in construction projects, such as floor slabs, rooftops, and walls. The substantial idea of CLT and its great strength properties give it the likelihood of being used in multistory structures. CLT can also be processed as a "ready-made" building material, tailoring its process to the precise required measurement to reduce wastage of building material